Machines | Free Full-Text | Improved Mesh Stiffness Method and Vibration Analysis of a Planetary Gear System with a Spatial Tooth Crack

Surface Contact Fatigue Failure Assessment in Spur Gears Using Lubricant Film Thickness and Vibration Signal Analysis - IIT Madras

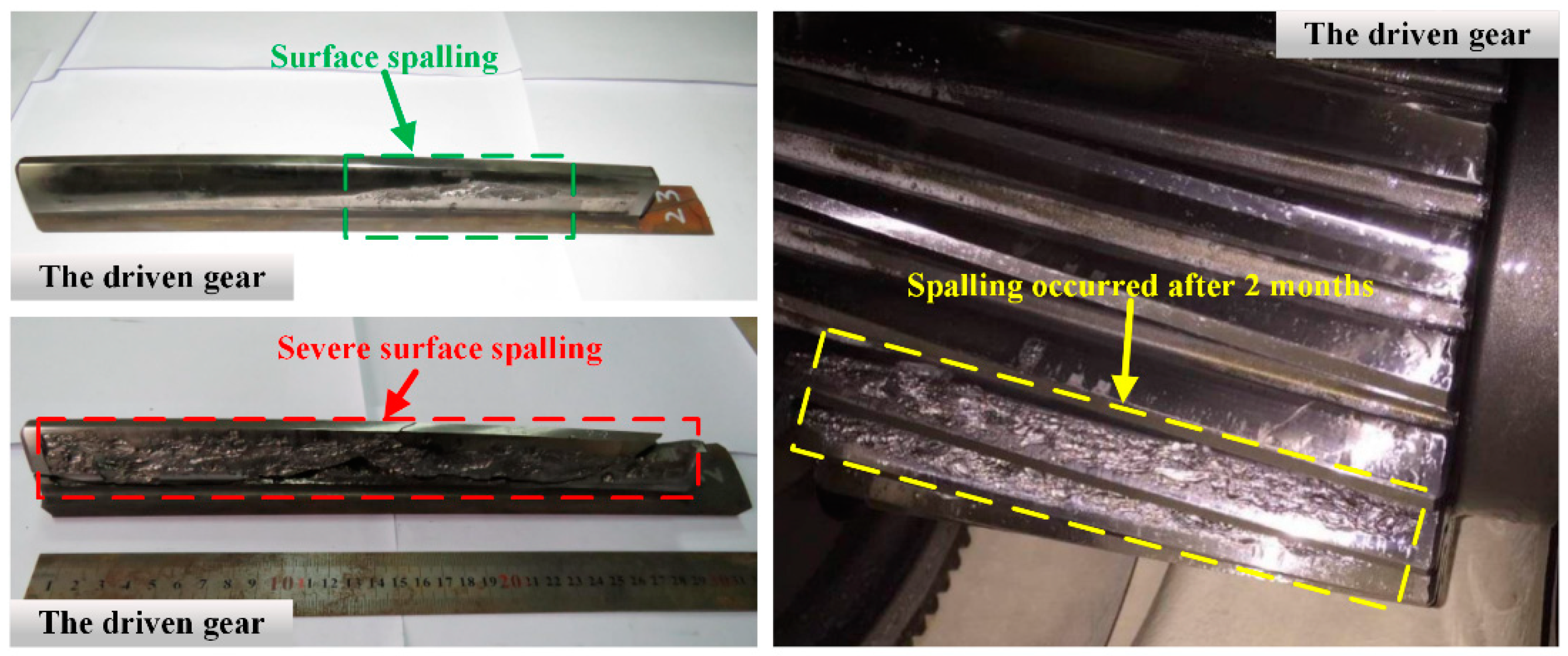

Pitting [1] c) Spalling: Spalling is one of the most destructive modes... | Download Scientific Diagram